Magnet audit, magnet inspection, and magnet testing are all related to the evaluation and analysis of magnets. These are all important aspects of ensuring the effectiveness and performance of magnets in various applications, such as motors, generators, sensors, and other electronic devices.

All of the processes are important processes for industries that rely on magnets in their operations. These processes ensure that the magnets are functioning properly, are safe to use, and meet industry standards.

Magnet Audit

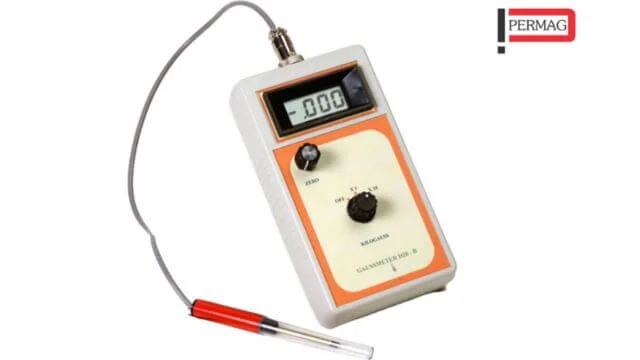

A Magnet Audit is a process that evaluates the condition and performance of magnets used in industrial applications. It involves a detailed examination of the magnet, including its design, installation, and maintenance. The audit aims to identify any defects or issues that may impact the magnet’s performance or safety. The audit may involve the use of a specialized digital gaussmeter, such as a magnetic field strength meter, to measure the magnet’s strength and polarity. After the audit, a report is generated that outlines any issues found and provides recommendations for corrective action.

Magnet Inspection

Magnet Inspection is a process that involves a visual examination of magnets to ensure they are free from defects and damage. This inspection is typically carried out as part of a regular maintenance program to identify any issues before they become a problem. During the inspection, the magnet is checked for cracks, chips, or other signs of wear and tear. The inspector may also check the magnet’s polarity and strength using a specialized digital gaussmeter. If any issues are found, the inspector will recommend corrective action.

Magnet Testing

Magnet Testing involves the use of a specialized digital gaussmeter to test the performance of magnets. The testing can be carried out on new magnets to ensure they meet industry standards, or on existing magnets to determine their strength and polarity. The testing process may involve the use of magnetic field strength meters, gauss meters, and other instruments. The results of the testing are used to determine the magnet’s magnetic field strength, flux density, and other performance characteristics. If any issues are found, the magnet may need to be repaired or replaced.

Importance of Magnet Testing, Inspection and Audit

Magnet Audit, Magnet Inspection, and Magnet Testing are important for several reasons:

Safety: Magnets are used in a variety of industrial applications, from manufacturing to medical devices. Ensuring that magnets are functioning properly and free from defects is critical for the safety of workers and consumers who may come into contact with the magnets.

Compliance: Many industries have regulations and standards that govern the use of magnets. Magnet Audit, Inspection, and Testing help ensure that the magnets meet these standards and comply with regulations.

Efficiency: Magnets are often used in high-precision applications where even small variations in magnetic strength or polarity can have a significant impact on performance. Magnet Audit, Inspection, and Testing can help identify issues before they become a problem, reducing downtime and improving overall efficiency.

Cost Savings: Regular maintenance and testing of magnets can help extend their lifespan and prevent the need for costly repairs or replacements. It can also help identify opportunities for optimization and cost savings in the use of magnets.

Quality Control: Magnets are often used in high-precision applications where their strength and polarity must be tightly controlled. Magnet Audit, Inspection, and Testing can help ensure that magnets meet the necessary quality standards and are suitable for use in these applications.

Predictive Maintenance: Magnet Audit, Inspection, and Testing can be used as part of a predictive maintenance program to identify potential issues before they cause problems. By monitoring the condition and performance of magnets, businesses can schedule maintenance and repairs when they are needed, rather than waiting for a failure to occur.

Risk Management: Magnets are often used in critical applications where a failure could have serious consequences, such as in medical devices or aerospace applications. Magnet Audit, Inspection, and Testing can help identify and mitigate these risks, reducing the likelihood of a failure occurring.

Customer Satisfaction: Businesses that rely on magnets to produce their products or provide their services must ensure that their magnets are of high quality and perform as expected. Magnet Audit, Inspection, and Testing can help businesses meet these expectations and maintain customer satisfaction.

Reputation: A failure involving magnets can damage a business’s reputation and lead to lost business. Magnet Audit, Inspection, and Testing can help businesses avoid these issues by ensuring that their magnets are safe, reliable, and of high quality.

Conclusion

Magnet Audit, Magnet Inspection, and Magnet Testing are important processes for industries that rely on magnets in their operations. These processes ensure that the magnets are functioning properly, are safe to use, and meet industry standards.

A regular maintenance program that includes these processes can help extend the life of magnets, reduce downtime, and improve the overall efficiency of industrial operations. It is important to work with a qualified professional who has the expertise and specialized equipment to carry out these processes effectively.

These are important for a variety of reasons, including safety, compliance, efficiency, cost savings, quality control, predictive maintenance, risk management, customer satisfaction, and reputation. By investing in these processes, businesses can ensure that they are operating at their best and reduce the risk of costly failures or accidents.

Magnet Testing with Permag today!

Your magnets will ultimately lose their strength over time, necessitating tests to certify the equipment’s performance. Want to boost the cleanliness of your equipment and, by extension, equipment safety? You have fortunately found the correct place.

Permag Products, a renowned manufacturer of magnetic equipment in India, specializes in magnet testing to provide high-quality magnets for a number of sectors.

We will help you choose the ideal magnet for your needs. You can reach us via email at ho@permagproducts.com OR by visiting our website.