Rare Earth Roll Separator

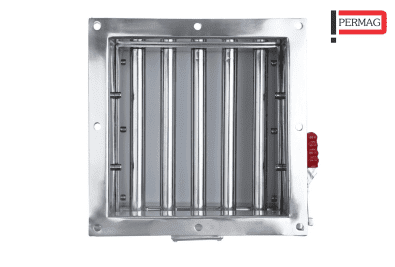

PERMAG’s Rare earth roll separator provides a unique inclined belt feeding system to maximize overall performance and efficiency.

The design of the magnetic rolls ensures the optimum combination of magnetic field strength and magnetic gradient to give the most effective separation.

FEATURES

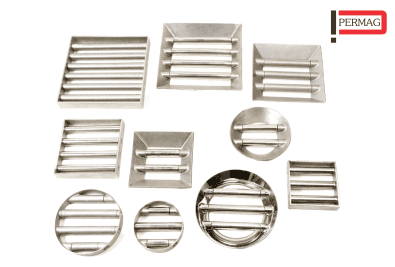

Related Products

FAQ'S

The Rare Earth Roll Separator is used to separate weakly or para magnetic minerals from non-magnetic minerals in a dry state. These non-metallic minerals are widely used in the production of ceramics, plastics, glass, cosmetics, paper, and many other commonly used materials

PERMAG’s Rare earth roll separator Standard models include single, double, and triple stage machines also multiple separation stages available on one separator. The design of the magnetic rolls ensures the optimum combination of magnetic field strength and magnetic gradient to give the most effective separation.

The mono-layer of material is carried onto a high intensity permanent magnetic head roll. Magnetic material is attracted to the magnetic field of the roll. This attraction changes the trajectory of the magnetically attracted minerals away from that of the non-magnetic material.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.