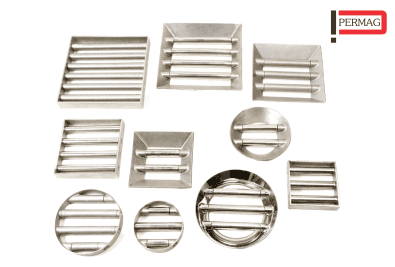

DRAWER TYPE MAGNETIC GRILL

PERMAG’s drawer type magnetic grill provides powerful magnetic separation suitable for mechanical and gravity flow applications in all industries. Drawer type magnetic grill play an important role to remove medium and fine ferrous contamination from dry, free-flowing products. Drawer type magnetic grill are made to be placed at critical points to remove metal contamination from product streams and guarantee the product quality and prevent damage to machines.

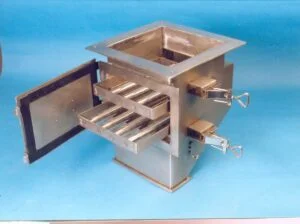

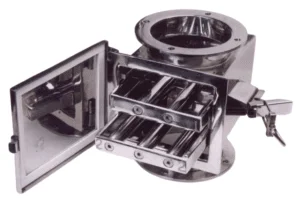

Drawer type magnetic grill are equipped with high-power magnetic cartridges, configured with arrangements of two or more cartridge trays that are staggered to increase contact with the product stream. The material moves in a zig-zag pattern from one cartridge tray to the next, to maximize the removal of ferrous contamination.

HOW DRAWER TYPE MAGNETIC GRILL WORKS

PERMAG’s drawer type magnetic grill are built with very high power RE magnetic cartridges fitted in SS housing. 1” diameter magnetic tubes are designed to create an extremely effective magnetic circuit. These cartridges are mounted in the middle of the free-fall pipeline, they are located in the centre of the product stream. This ensures that the product always passes very close to one or more magnets and prevent bridging or choking of the product stream.

The hinged door can be quickly unlatched and opened to allow quick removal and cleaning of each drawer magnet.

ADVANTAGES OF DRAWER TYPE MAGNETIC GRILL

TECHNICAL DATA SHEET OF DRAWER TYPE MAGNETIC GRILL

FEATURES OF DRAWER TYPE MAGNETIC GRILL

CLEANING OF DRAWER TYPE MAGNETIC GRILL

What is Drawer type magnetic grill?

Drawer type magnetic grill are built with powerful magnetic cartridges that are scattered across multiple trays. This setup allows for maximal contact with the moving product stream, which increases the efficiency with which ferrous contaminants are removed. The material travels in a zigzag path through the separator, shifting from one cartridge tray to the next. By exposing the material to many magnetic capture sites, this setup improves the material’s overall cleanliness.

The Drawer type magnetic grill versatility in both mechanical and gravity-based flow applications is one of its many strengths. Because of its adaptability, it can be used in a wide variety of manufacturing settings with little to no modification. The Drawer type magnetic grill continues to be successful regardless of whether the material is being transported via pipes, chutes, or free-fall routes.

Features of Drawer type magnetic grill and Drawer Magnet

Preserving the quality of a product is crucial in a wide variety of sectors, including the food and beverage, pharmaceutical, plastics, ceramics, minerals, and other processing industries. Metal particles are just one example of a contaminant that can reduce product quality, put a company in breach of regulations, and cause expensive equipment problems and downtime. To solve these problems, manufacturers have developed the Magnetic Drawer type magnetic grill, which uses cutting-edge magnetic technology to attract and trap ferrous impurities during key stages of manufacturing.

The drawer divider has characteristics that make it easy to clean and use. The layout allows for simple access while cleaning or replacing cartridges, reducing the amount of time needed for these tasks to occur. The separator’s durability and dependability in harsh industrial settings are the result of its sturdy design and high-quality components.

Why choose us for Drawer type magnetic grill

The PERMAG MDrawer type magnetic grill is an effective and dependable answer to the problem of magnetic separation in a wide range of business and industrial settings. The ability to selectively remove ferrous impurities from dry, free-flowing products is an important step towards preserving product quality, conforming to standards in the industry, and safeguarding subsequent processing steps. Its ability to guarantee a contaminant-free final product is attested to by its cutting-edge design, powerful magnetic cartridges, and flexible setup.

PERMAG’s Drawer type magnetic grill is a reliable and effective tool for magnetic separation in many sectors. This drawer separator is great for extracting medium and fine ferrous impurities from dry, free-flowing materials thanks to its adaptable design and powerful magnetic capabilities. Positioned at key points in production lines, it prevents metal particles from reaching downstream machinery and keeps products free of flaws.

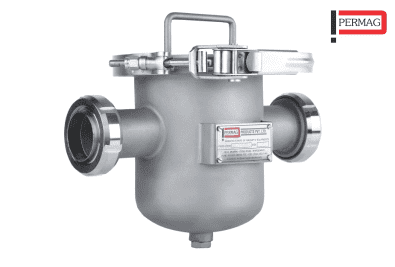

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnetic Audit, Magnetic Testing, and Magnetic Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

The Drawer type magnetic grill are built with very high power RE Magnetic cartridges fitted in SS housing. These cartridges are mounted in the middle of the free-fall pipeline, they are located in the centre of the product stream. This ensures that the product always passes very close to one or more magnets and prevent bridging or choking of the product stream.

Drawer Type is the main type of magnetic separator that provides powerful drawer separator suitable for mechanical and gravity flow applications in all industries. Magnetic separators play an important role to remove medium and fine ferrous containments from dry, free-flowing products.

Established in 1985, Permag Products Pvt. Ltd take pride in the quality, strength, reliability, and durability of our products and strive hard to uphold the reputation and trust of our 2500 plus customers all over the globe. Permag is a worldwide leader in the design & manufacturing of high-performance drawer type magnetic grill for a variety of industries in more than 20 countries.

Videos

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.