SUSPENDED MAGNET

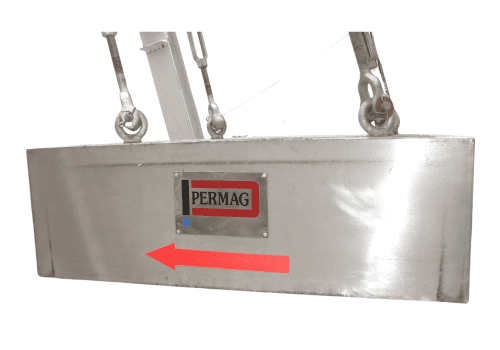

Belt conveyors, vibrating feeders, and chutes can all benefit from the use of a magnet suspended to remove ferrous impurities from a delivered stream of material.

Different sizes and strengths of customized designs are available to consider the form, size, and speed of raw material and load depth in order to ensure perfect fitment and optimal efficacy for specific applications. Magnetic field strength and holding force are maximized in our product designs. Suspended magnets eliminate iron contamination from materials such as nuts, bolts, foundry sand, glass cullet, and more. This makes the task of being magnet suspended easier. We deal in suspended magnets and spout magnets which help in removing ferrous metals from granular and powder products during pipeline transit.

FEATURES SUSPENDED MAGNET

High-strength strontium ferrite magnet is used in its construction.

Quite simple to set up and utilize

There’s no need to worry about it.

Forces with the greatest reach and holding power

There are no additional products needed for the process.

Sizes can be customized to meet specific needs.

To run, there are no wires or cables required.

Purchase, operation, and maintenance costs are lower.

Full height adjustment is available.

ADVANTAGES SUSPENDED MAGNET

Prevent damage to processing equipment

Protects products from metallic contamination.

Lower maintenance expenses

Boost productivity by reducing energy consumption.

What is a Suspended Magnet?

A suspended magnet is a magnetic separator that is suspended over a conveyor belt to attract and remove magnetic materials from the conveyed material stream.

High Strength Suspended Magnet from Permag

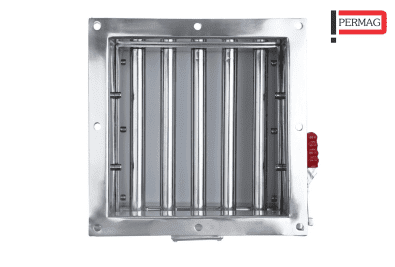

Suspended Magnet are an essential tool for many industries that require the removal of ferrous impurities from their raw materials. The use of these magnets can help ensure product purity and prevent damage to downstream equipment. We offer a range of customized designs for suspended magnets that are tailored to specific applications. Our team of experts takes into consideration the form, size, and speed of the raw material and load depth to ensure a perfect fit and optimal efficacy.

Removal of Iron Contamination with Suspended Magnet

Suspended magnet are designed with maximum magnetic field strength and holding force, ensuring the most efficient removal of iron contamination from materials such as nuts, bolts, foundry sand, and glass cullet. This makes the task of being magnet suspended easier and more effective. In addition to suspended magnet, we also offer spout magnets, which are specifically designed to remove ferrous metals from granular and powder products during pipeline transit. This ensures that these materials remain pure and free from any impurities that could impact product quality.

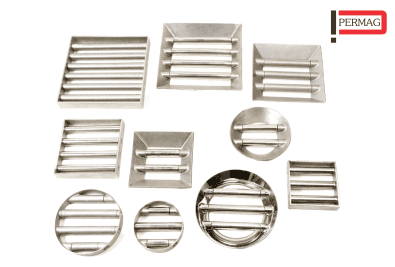

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnet Audit, Magnet Testing, and Magnet Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Permag Products for best Suspended Magnet

At Permag Products, we take great pride in providing our customers with high-quality suspended magnets and spout magnets that are designed to meet their unique needs and specifications. Our team of experts is dedicated to ensuring that our products are not only effective but also reliable and easy to use. Contact us today to learn more about our suspended magnets and how they can benefit your business.

Related Products

FAQ'S

The right suspended magnet for your application will depend on several factors, such as the size and type of material being conveyed, the flow rate of the material, and the strength of the magnetic field required to remove the magnetic material. It is best to consult with a magnetic separator manufacturer or supplier to determine the best magnet for your specific application.

Typically, suspended magnet are positioned above a conveyor belt or other material-handling machinery. Suspended by chains or other support structures, the magnet must be positioned in close proximity to the conveyed material in order to effectively remove magnetic particles. It is essential to adhere to the installation instructions and safety guidelines provided by the manufacturer. It is suggested that an experienced individual perform the installation. Permag Products can help you get Suspended Magnets up and running and keep them in good condition.

To ensure that a suspended magnet continues to operate effectively, it is essential that it receives the proper care and attention. Regular cleaning of the magnet is required to eradicate any magnetic material buildup. Additionally, it is essential to periodically inspect the magnet’s strength and replace any deteriorated or damaged components. Follow the manufacturer’s maintenance instructions and schedule routine maintenance inspections.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.