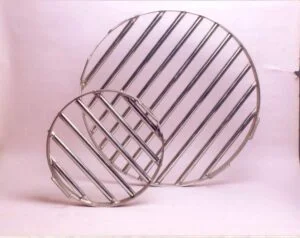

MAGNETIC GRILL

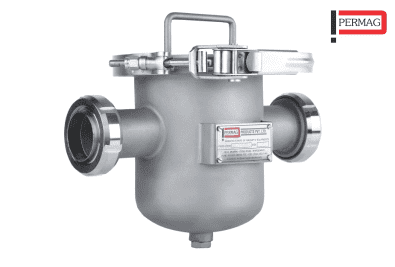

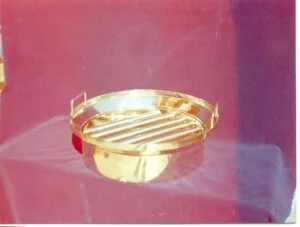

Magnetic grill from PERMAG enables effective magnetic separation for mechanical and gravity flow applications in all industries. Magnet grills, grate magnet can be installed or laid down inside hoppers, pits, chutes, housings, and bins, where they are easily accessible for cleaning.

Powders and granules that are free-flowing are filtered of ultrafine ferrous impurities by a hopper magnet. Permag’s designs maximize equipment to capture, control, and protection while enhancing product purity. We are the Magnetic Grill Manufacturer. A magnetic grill is most effective when the product is dry, free-flowing, and does not bridge between the magnetic tubes.

HOW MAGNETIC GRILL WORKS

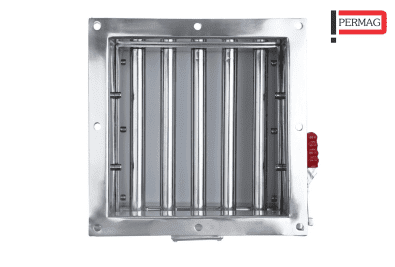

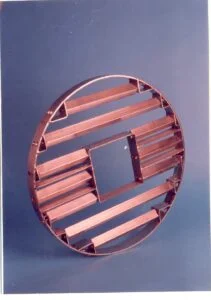

Magnetic grills by PERMAG are constructed with exceptionally powerful RE magnetic cartridges set in an SS frame with 1″-diameter magnetic tubes to create a highly effective magnetic circuit. These magnetic grills can be put right in the product flow, allowing items to come into direct touch with them.

By detaching the magnetic grill from its process and pushing the contamination towards the non-magnetic portion of each rod, the contamination is eliminated. This will release the majority of contaminants that have been attracted.

ADVANTAGES OF MAGNETIC GRILL

Magnetic flux circuit geometry ensures the controlled accumulation of contaminants, which lowers product stream bridging or clogging.

Removing ferrous material extends the life of machinery.

Significant decrease of ferrous particles passing through magnetic grills.

Reduce downtime and improve output

TECHNICAL DATA SHEET OF MAGNETIC GRILL

Magnet used – Nd-Fe-B (Rare earth)

Grade – N 52M (Highest grade)

Available in round, half round, square & rectangular size

304 / 316 Stainless steel is available for corrosive environments

1” Dia magnetic tubes fitted in SS frames

FEATURES OF MAGNETIC GRILL

304 / 316 All-stainless steel, welded structure

Available in round, square, and rectangle dimensions

Extremely potent premium grade N52M rare earth magnets

Available in 12000 Gauss

Can withstand temperatures up to 100°C

Simple to instal and requiring no maintenance

Remove up to 30 microns of metal.

Superior filtration performance

Simple to clean

Custom length & width dimensions are available.

What is a Magnetic Grill?

A magnetic grill is a device that separates iron particles from dry, granular, or free-flowing materials. It is very beneficial in areas including food processing, medicines, mining, and recycling. The magnetic grill attracts iron and ferrous particles in the material to be treated. These particles are captured by the magnetic rods, preventing contamination.

Why Choose Us Hopper Magnet

Hopper magnets are essential for separating iron particles from various materials, including dry, granular, and free-flowing substances. At Permag Products, we take pride in being one of the premier manufacturers of magnetic grills and suppliers of magnetic rods in India. Hopper magnet are put to use for the purpose of separating iron particles from other types of materials, including those that are dry, granular, or free-flowing. We are one of the best magnetic grill manufacturers and magnetic rod suppliers in India. Our Magnetic Grill also known as hopper magnetic grill can be created using either a round, square, or rectangular frame made of stainless steel and magnetic rods placed inside of the frame.These grills are available to customers for installation into the hopper magnet or material feeding duct. In addition, we offer a grill of bespoke design complete with a test certificate, which may be fitted to circular ducts or pipes.

Grate magnets are essential tools for maintaining the purity and quality of materials in various industrial processes. By effectively removing iron particles from dry, granular, and free-flowing substances, grate magnets play a crucial role in ensuring the efficiency and reliability of your operations.

Characteristics of hopper magnet

The hopper magnet are constructed from neodymium Magnets, each of which is positioned within a frame of the appropriate size. Stainless steel is used in the construction of each and every component. It is also possible to have the overall structure of the grate magnet customized to the dimensions and specifications of the customer.

Key Features of Our Grate Magnets

- High-Strength Neodymium Magnets: Our grate magnets use powerful neodymium magnets to capture even the smallest iron particles, ensuring maximum purity of your materials.

- Durable Stainless Steel Construction: The stainless steel frame provides excellent corrosion resistance and durability, making our grate magnets suitable for a wide range of industrial applications.

- Customizable Design: We offer customizable grate magnets to fit specific dimensions and requirements, ensuring seamless integration into your existing systems.

- Easy Installation and Maintenance: Our grate magnets are designed for easy installation and maintenance, helping you minimize downtime and maintain optimal performance.

Benefits of Using Grate Magnets

- Improved Product Quality: By removing iron contaminants, grate magnets help maintain the quality and integrity of your products.

- Enhanced Operational Efficiency: With reduced risk of equipment damage caused by ferrous particles, your operations can run more smoothly and efficiently.

- Cost Savings: Preventing iron particles from entering your processing line can help avoid costly repairs and downtime, leading to significant cost savings.

- Versatility: Grate magnets are suitable for a wide range of applications, including food processing, pharmaceuticals, plastics, and chemical industries.

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnetic Audit, Magnetic Testing, and Magnetic Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

Magnetic grills from PERMAG work well for mechanical and gravity flow applications in all industries that need magnetic separation. Permag’s designs make the most of the equipment’s ability to capture, control, and protect while improving the purity of the product. We are one of the best companies that makes Magnetic Grills. When the product is dry, easy to move, and doesn’t get stuck between the magnetic tubes, a magnetic grill works best.

| Round Magnet Grills |

| Rectangular Magnet Grills |

| Square Magnetic Grill |

| Easy-Cleaning Magnetic Grill |

The price of Magnetic Grill varies according to the size of the dimensions of the Magnetic Grill required. Permag Magnetic grills are one of the best for all industries, If you want to know more about the magnetic grill, then you can contact us at ho@permagproducts.com

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.