MAGNETIC ROD

Magnetic rod from PERMAG are a simple and inexpensive method of magnetic separation. PERMAG magnetic rod or neodymium rod magnet achieve the optimal balance between magnetic strength and holding force due to software-assisted design.

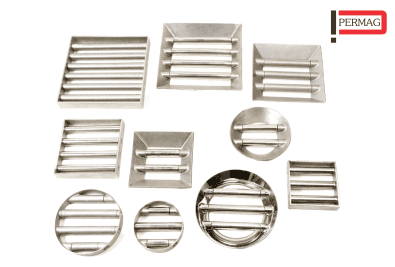

These rods can be put singly, next to one another, or in many rows. Our magnetic rod are utilized extensively in the food, pharmaceutical, dairy, chemical, and plastics processing industries.

As a Magnet rod supplier, Magnetic rod suppliers Or Magnetic rod Manufacturers, We make magnetic rods to the exact length specified by the customer.

HOW MAGNETIC ROD WORKS

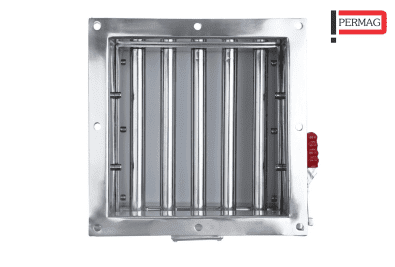

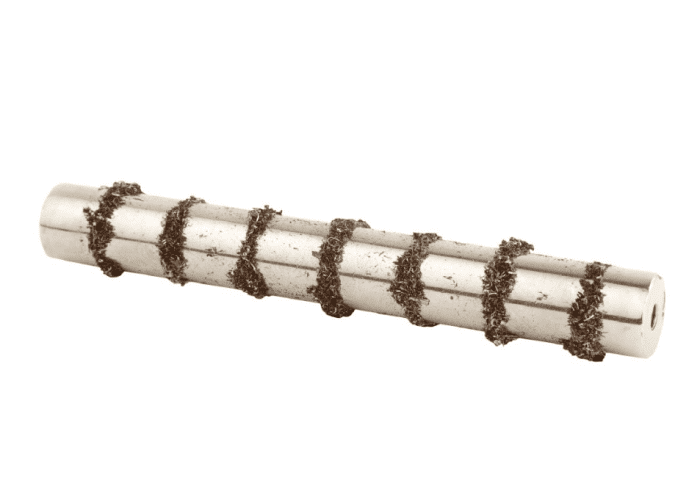

Magnetic Rod by PERMAG are constructed with extremely powerful RE magnets integrated in SS 304/316 tubes. Magnetic tubes with a 1″ diameter are designed to generate a highly efficient magnetic circuit. These magnetic rods will be utilized for gravity free-fall magnetic separation applications. All ferrous particles, including bolts, nuts, chips, and harmful tramp iron, can be successfully captured and stored.

Magnetic Rod offer flat surfaces that are simple to clean. Depending on their configuration, rod magnets can be cleaned in seconds by simply pushing any contamination that has been attracted to one end; this will release any contamination that has been attracted.

Magnetic Rod have smooth surface that’s easy to clean. Depending on configuration, rod magnets can be cleaned in seconds by simply pushing the attracted contamination to one end, this will release any attracted contamination.

ADVANTAGES OF MAGNETIC ROD

Removes extremely fine ferrous impurities from bulk material

Reduction in downtime and improvement in output

The elimination of ferrous material enhances the lifespan of machinery.

TECHNICAL DATA SHEET OF NEODYMIUM ROD MAGNET

Magnet used – Nd-Fe-B (Rare earth)

Grade – N 52M (Highest grade)

FEATURES OF NEODYMIUM ROD MAGNET

304 / 316 All-stainless steel, welded structure

Extremely potent premium grade N52M rare earth magnets

Available with 3000, 6000, 8000, 10000, and 12000 Gauss

Working temperature grade: 80, 100, 120, 150 degree Celsius

Simple to instal and requiring no maintenance

Remove up to 30 microns of metal

Superior filtration performance

Simple to clean

Custom length and diameter dimensions are available.

What is a Magnetic Rod?

The magnetic rod is commonly used to remove ferrous contaminants from liquids and semi-liquids, as well as to filter tiny powders of any kind. Among the many industries that make use of magnetic rods are those dealing with plastics, food, environmental protection, filtration, chemicals, electricity, construction supplies, tiles, pills, minerals, coal, and so on.

Why Choose Us for Neodymium Rod Magnet?

When it comes to magnetic strengths as well as precision in dimensioning, Permag’s magnetic rods are among the best in the world. We are one of the best magnetic rod manufacturers and magnetic rod suppliers in India. Neodymium Rod Magnet are either high-intensity rare earth magnets or hard ferrite ceramic magnets. It is also possible to tailor the overall structure of the magnetic grills to the dimensions and specifications provided by the customer. These magnetic rods are at the core of both our Magnetic grills and Magnetic Filters; they are optimized to manage high flow rates and high levels of ferrous material deposition.

Characteristics of Neodymium Rod Magnet

The Neodymium Rod Magnet will be simple to clean, there will be no costs associated with their maintenance, and they will save costly shutdowns and delays for equipment farther down the process line. No power expense. The installation of these Magnetic Rod helps to improve product quality, which in turn increases product value, and contributes to compliance with FDA rules and the regulations of other governments and customers regarding iron contamination levels.

Benefits of Using Neodymium Rod Magnets

Improved Product Quality

By incorporating Neodymium Rod Magnets into your processes, you can significantly improve the quality of your final products. These magnets effectively remove ferrous contaminants, ensuring that your products meet the highest standards of purity and quality.

Increased Operational Efficiency

Neodymium Rod Magnets enhance the efficiency of your manufacturing processes by preventing equipment damage and reducing downtime. Their powerful magnetic force ensures consistent performance, leading to smoother and more reliable operations.

Compliance with Regulations

Using Neodymium Rod Magnets helps you comply with industry regulations and standards, such as FDA guidelines for iron contamination. This not only protects your business from regulatory issues but also enhances your reputation for producing safe and high-quality products.

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnetic Audit, Magnetic Testing, and Magnetic Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

Removes extremely fine ferrous impurities from bulk material

Reduction in downtime and improvement in output

The elimination of ferrous material enhances the lifespan of machinery.

You need to consider following factors to Consider When Choosing a Magnetic Rod

Capacity.

Safety features.

Sample viscosity.

Temperature range.

Accuracy.

Magnetic Rods by PERMAG are constructed with extremely powerful RE magnets integrated in SS 304/316 tubes. Magnetic tubes with a 1″ diameter are designed to generate a highly efficient magnetic circuit. These magnetic rods will be utilized for gravity free-fall magnetic separation applications. All ferrous particles, including bolts, nuts, chips, and harmful tramp iron, can be successfully captured and stored.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.