ROTARY MAGNET

It is PERMAG’s Rotary magnet separator that is utilized in vertical process lines to remove ferrous particles from substances that are susceptible to bridging or caking.

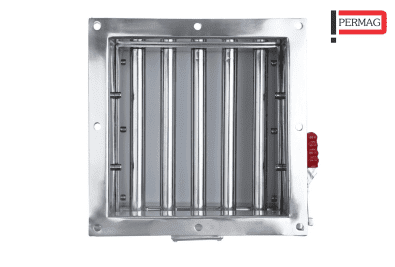

Rotary magnet separators contain a centrally positioned Magnetic cartridge assembly arranged around and parallel to the rotational axis of rotation. The size of the inlet and outflow determines the number of rods needed. Motor power is used to rotate this sturdy magnetic cartridge assembly. While the product is passing through, the rotary magnet rotates the powerful magnetic cartridges. Clogging, caking, and bridging-prone materials with high viscosity or low fluidity can be easily removed with this method.

HOW IT WORKS

The rotating assembly is located in the center of the device. Overlapping and perpendicularly aligned magnetic rods form an inverted wheel. The inlet and exit sizes determine the number of rods required.

The product is gently agitated while the assembly rotates. Blockages are avoided because of this agitation. Materials like starch and other granular substances can be treated using the machine.

In order to clean, all you have to do is open the door and remove the assembly. Remove the assembly’s magnetic rods. To enable inspection or additional study of any captured contaminants, it will be liberated and released into the environment.

ADVANTAGES

Prevents clots from forming on the pipes.

Allows for the screening of even the most challenging items; removes impurities as small as 1 micron

Extends the life of machinery by removing ferrous content.

Maintain a high level of efficiency

FEATURES

Installation and maintenance are a breeze.

Construction of high-quality stainless steel

Magnetic materials of the highest quality made from rare earth elements

Inspection and maintenance can be carried out with ease.

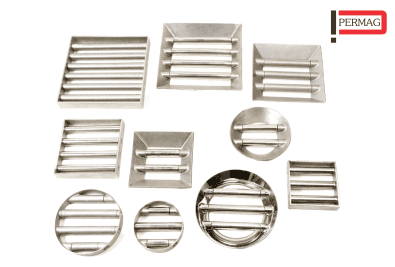

Round flange or square chute

Made to match a particular application’s needs

All NORD gearmotors and Bonfiglioli gearboxes are made by NORD and Siemens.

TECHNICAL DATA SHEET

Magnetic strength – 11500 to 12000 Gauss variants available as per requirement.

Magnet used – Nd-Fe-B (Rare earth)

Grade – N 52M (Highest grade)

Temperature – Up to 100°C (Magnets available as per requirement for high temperature)

Surface Finish – Mirror / glass bead

Inlet / outlet connection – Flange

High grade FDA approved gaskets.

Heavy duty SS toggle clamps for locking.

Related Products

FAQ'S

The rotating assembly is located in the center of the device. Overlapping and perpendicularly aligned magnetic rods form an inverted wheel. The inlet and exit sizes determine the number of rods required. The product is gently agitated while the assembly rotates.

Prevents clots from forming on the pipes.

Allows for the screening of even the most challenging items; removes impurities as small as 1 micron

Extends the life of machinery by removing ferrous content.

Maintain a high level of efficiency

PERMAG’s Rotary magnetic separator is an inline magnetic separator used in vertical process lines for the extraction of ferrous particles from difficult to process substances that are prone to bridging or caking.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.