BULLET MAGNET

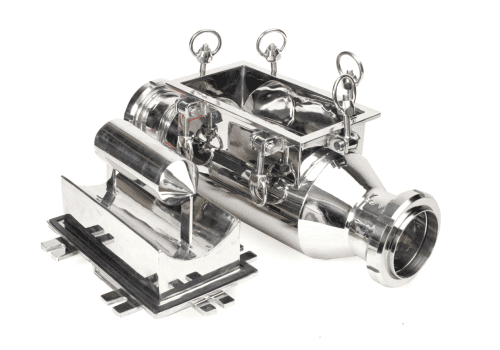

The Bullet magnet from PERMAG is designed with an aerodynamic shape that enables it to remove maximum ferrous contamination from pneumatic lines without impeding flow.

Housed bullet magnet or spout magnet are useful for removing tramp contaminants from gravity and pneumatically transported pipes, such as nuts, bolts, and staples. A magnetic bullet magnet element of high intensity is centrally positioned within a stainless steel casing.

The design assures that the magnetic element has no effect on the product flow.

HOW BULLET MAGNET WORKS

The nose cone redirects the material around the cylindrical magnet, where it passes through the magnetic field and is attracted to the magnetic surface by ferrous impurities. This magnet is ideal for dry and semi-dry powders, granules, and chunks.

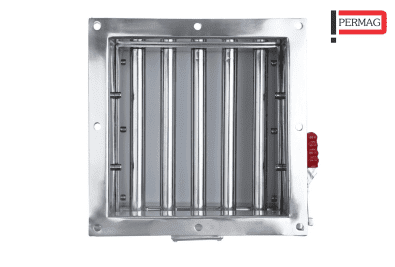

The bullet magnet is manually cleanable. To gain access to the bullet element, release the door’s locking toggle clamps and open the door. All contaminants that were attracted can now be removed.

ADVANTAGES BULLET MAGNET

Protect processing equipment from damage

Guarantees metal-free product

Reduce maintenance expenses & reduces energy usage

Reduce downtime and improve output

TECHNICAL DATA SHEET OF BULLET MAGNET

Magnet used – Nd-Fe-B (Rare earth)

Grade – N 52M (Highest grade)

Available in flange, SMS Union Or TC clamp connection

FEATURES OF BULLET MAGNET

Finely polished and well-welded to fulfill food grade standards.

Heavy-duty locks for simple installation and upkeep

Highly efficient and reliable performance

Hygienic, hermetically sealed, quick-release door

Housing available in SS 304 / 316

Equipped with powerful rare earth magnets

Available in sizes tailored to user specifications

Simple to inspect

What is Bullet Magnet and how can it help?

When it comes to removing ferrous metal impurities from dry bulk materials, bullet magnets, also known as spout magnets, are the magnetic separator of choice in all industrial settings. To prevent damage to subsequent machinery or final products, this device uses a high magnetic field to attract and collect ferrous particles such as iron and steel.

Why Choose Bullet Magnet ?

When it comes to offering a bullet magnet separator or Spout Magnet, the first thing we do is confer with the customer to identify the necessary parameters. These parameters include the size of the line, the pressure within the line, the size of the product, the temperature, and the tonnes per hour. After that, we tailor our drawings to client applications and submit them for approval before we begin production.

Characteristics of Bullet Magnet

The Bullet Magnet also called Bullet Magnet is a gravity fed or pneumatic pipeline magnetic separator that is both space-saving and highly effective in removing ferrous metal pollution. It is typically used in pneumatic process lines, frequently for food powders, as well as high-velocity intake lines in places where abrasive materials, such as wheat, can be an issue. Because they need to be cleaned on a regular basis, the magnets have been arranged in such a way that provides easy access to them.

The dry, free-flowing product travels through the body of the separator made of stainless steel and then passes over the bullet magnet, which is responsible for removing the contamination from the product. Both a horizontal and a vertical orientation are possible for the magnetic separators, with the flow either going up or down. Internal deflectors make certain that the product is rerouted over the bullet magnet with the least amount of turbulence possible and without any obstructions.

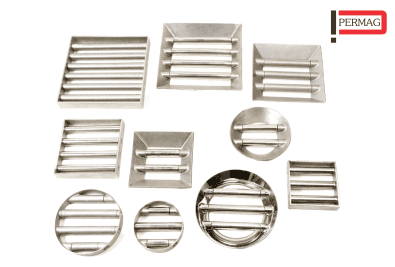

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Bullet magnet Magnetic Filters and Fixturers. Additionally, we offer Magnet Audit, Magnet Testing, and Magnet Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

The Bullet magnet is designed with an aerodynamic shape that enables it to remove maximum ferrous contamination from pneumatic lines without impeding flow. The design assures that the magnetic element has no effect on the product flow.

The nose cone bullet diverts the material around the cylindrical magnet where it passes through the magnetic field and ferrous contaminants are drawn to the magnetic surface.

Housed bullet magnets model OR Spout Magnets Model are best for removing tramp contaminants from gravity and pneumatically transported pipes, such as nuts, bolts, and staples. The design assures that the magnetic element has no effect on the product flow.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.