HUMP MAGNET

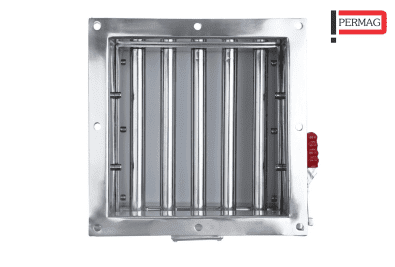

The typical Permag’s hump magnet comprises two plate magnets housed in an offset housing and fitted into vertical spouts. In order to gain access to the two plate magnets, the enclosure is hinged, locked, and gasketed. The product hits the face of the first plate magnet as it enters the housing, moves through the housing’s offset angle, and then hits the face of the second plate magnet. As a result, even abrasive or low-flowing materials can be separated effectively in large quantities.

The Hump magnet uses a pair of robust Spout Magnets coupled with diverter mechanisms. These magnets are strategically positioned to redirect the flow of product passing through the hump, so compelling it to interact with the magnetic fields. The Hump separators are manufactured with a durable stainless steel material and include a welded flange mounting mechanism that can be adjusted to fit either chute or pipe applications. These separators are offered in common sizes, and custom sizes can be accommodated upon request.

FEATURES OF HUMP MAGNET

Completely encased in stainless steel

Magnet options include ceramic and rare earth.

Stronger than a single magnet due to its dual magnet design.

Plate magnets with a movable hinge open for easy, hand-washing maintenance

Gasket material that meets FDA standards for use around food

ADVANTAGES OF HUMP MAGNET

The offset design disperses clumps of material and channels it toward the magnetic field.

The slanted design increases safety from entrapped ferrous contamination by funneling product flow into the magnetic field and preventing buildup and bridging.

What is Hump Magnet?

Hump magnet can withstand substantial amounts of both positive and negative pressure, as well as the pull of gravity. The hump magnet’s angled form helps avoid buildup and bridging by directing product flow towards the magnetic field.

Why Choose Us as one of the best Hump Magnet Manufacturer

In situations where the material is moving vertically, magnetic humps can be used. Separating ferrous metals from non-ferrous materials including granules, powder, food, and more is a common application for hump magnet. Hump Magnet are typically made up of two Plate Magnets fixed in a skewed housing and fitted into a vertical spout. Clean outflow material is guaranteed when the falling material strikes the first magnet, changes direction, and then falls over the second magnet.

The magnets are hinged, so they may be opened and closed for periodic cleaning. Any size of Pipe or duct can have a hump magnet made to fit it. Vertical spouts can benefit from Hump Magnet, which are made up of two Plate Magnet fitted in a staggered housing. Entering product strikes the face of the first Plate Magnet, moves through the housing’s offset angle, and strikes the face of the second Plate Magnet. As a result, even abrasive or low-flowing materials can be separated effectively in large quantities.

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnet Audit, Magnet Testing, and Magnet Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Installation of Hump Magnet

A common problem of Hump Magnets is that they need a wide, straight space in which to be installed. In order to gain access to the two Plate Magnet, the enclosure is hinged, locked, and gasketed. Since hump magnets are designed to be installed with minimal effort, you may avoid the lengthy downtime typically involved with setting up new machinery. You may rest assured that when you invest in one of our hump magnet, you are getting a high-quality, long-lasting magnetic separation device. In order to function properly, hump magnets must be installed in closed flow lines or on processing equipment, where they will be subject to the effects of gravity in a free-fall situation. We provide a wide variety of adapters that are custom-made to your specifications as part of our custom design services.

Characteristics of Hump Magnet

- Buildings made entirely of stainless steel

- The finest ceramic, Alnico, rare earth, neodymium iron boron, and samarium cobalt magnets available.

- Two magnets, twice the security

- Designing a double-trapped front face for defense.

- Inlet and exit flanges made of a durable stainless steel angle

- There are sturdy locks, hinges, and a handle for convenient opening and closing.

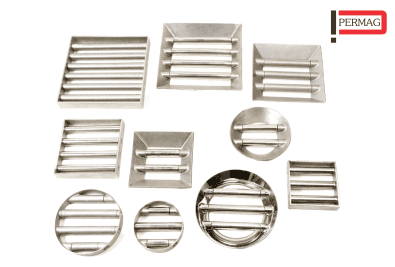

Related Products

FAQ'S

The ASA standard flanges are provided at inlet & outlet to install the hump into process line

As the material flows over the hump, the magnetic contaminants are attracted by the magnetic field and adhere to the magnetic surface of the plate magnets. Clean materials continue flowing freely, while magnetic contaminants are effectively separated.

Many hump magnets come with a manual cleaning mechanism. Periodically, you can slide out the magnet plates and wipe away the trapped metal contaminants. There are also self-cleaning models available.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.