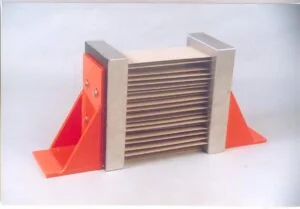

MAGNETIC SHEET FANNER

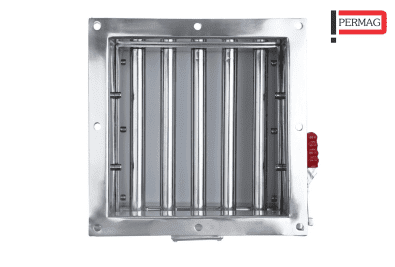

PERMAG’S Magnetic sheet fanner also known as magnetic sheet separators efficiently and safely separate stakes of greasy sheets. This avoids the risk of damage to the part or injury to the operator that could be incurred by prying apart each sheet individually. The magnetic field is so strong that it pulls the sheets away from each other by themselves. The variety of mounting configurations available is a direct result of the modular design.

A magnetic sheet fanner generates a strong magnetic field, which is subsequently applied to a stack of magnetic sheets made of ferrous steel. Due to the magnetic polarity’s repulsive force, the top sheet is forced away from the bottom layer. Magnetic sheet fanners generate such a strong magnetic force that even dirty or sticky sheets can’t stand a chance. Sheet fanners have a direct and positive impact on workplace productivity, security, and efficiency. Steel sheets present unique challenges, but with the help of our sheet fanners, you can avoid common pitfalls like scratching shiny sheets, struggling to pull them apart, and accidentally double-blanking them.

Features of Magnetic Sheet Fanner

Made of high-quality, durable materials such as stainless steel or aluminum.

They use a strong magnetic field to separate thin sheets of metal or other materials.

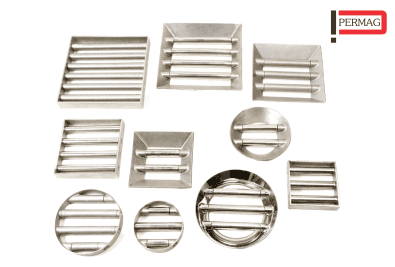

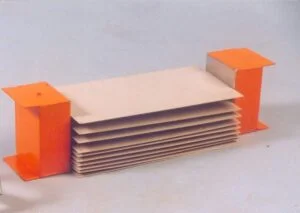

They are available in a variety of sizes and configurations to accommodate different sheet sizes and shapes.

Many models are designed to be modular, allowing for easy customization and integration with other manufacturing or industrial equipment.

Advantages of Magnetic Sheet Fanner

Highly efficient, saving time and reducing the risk of damage to sheets during handling.

They are a safe alternative to manually separating sheets, as they eliminate the need for operators to use force or potentially dangerous tools.

They can be used in a variety of industrial and manufacturing settings, from automotive plants to printing facilities.

Magnetic sheet separators/fanners can help to improve overall efficiency and productivity, as they ensure that each sheet is properly separated and ready for use.

How Magnetic Sheet Fanner works

Use a strong magnetic field to pull thin sheets of metal or other materials apart from each other.

The device is typically placed at the edge of a stack of sheets, and the magnetic field is activated to separate the sheets.

Once the sheets are separated, they can be easily removed from the stack and used for their intended purpose.

The magnetic field can be adjusted to accommodate different types of sheets and to achieve the desired separation force.

What is a Magnetic sheet fanner?

A magnetic sheet fanner is a device that uses magnetic force to separate and fan out stacked sheets of ferrous materials, such as steel, making it easier to pick individual sheets from the stack.

Organize and Separate Metal sheets with Magnetic Sheet Fanner

Magnetic sheet separator and fanners use magnets to separate thin sheets of metal or other materials. These devices can be useful in manufacturing or industrial settings where large stacks of metal sheets need to be organized and separated. They can also help to prevent damage to the sheets by reducing the amount of friction between them.

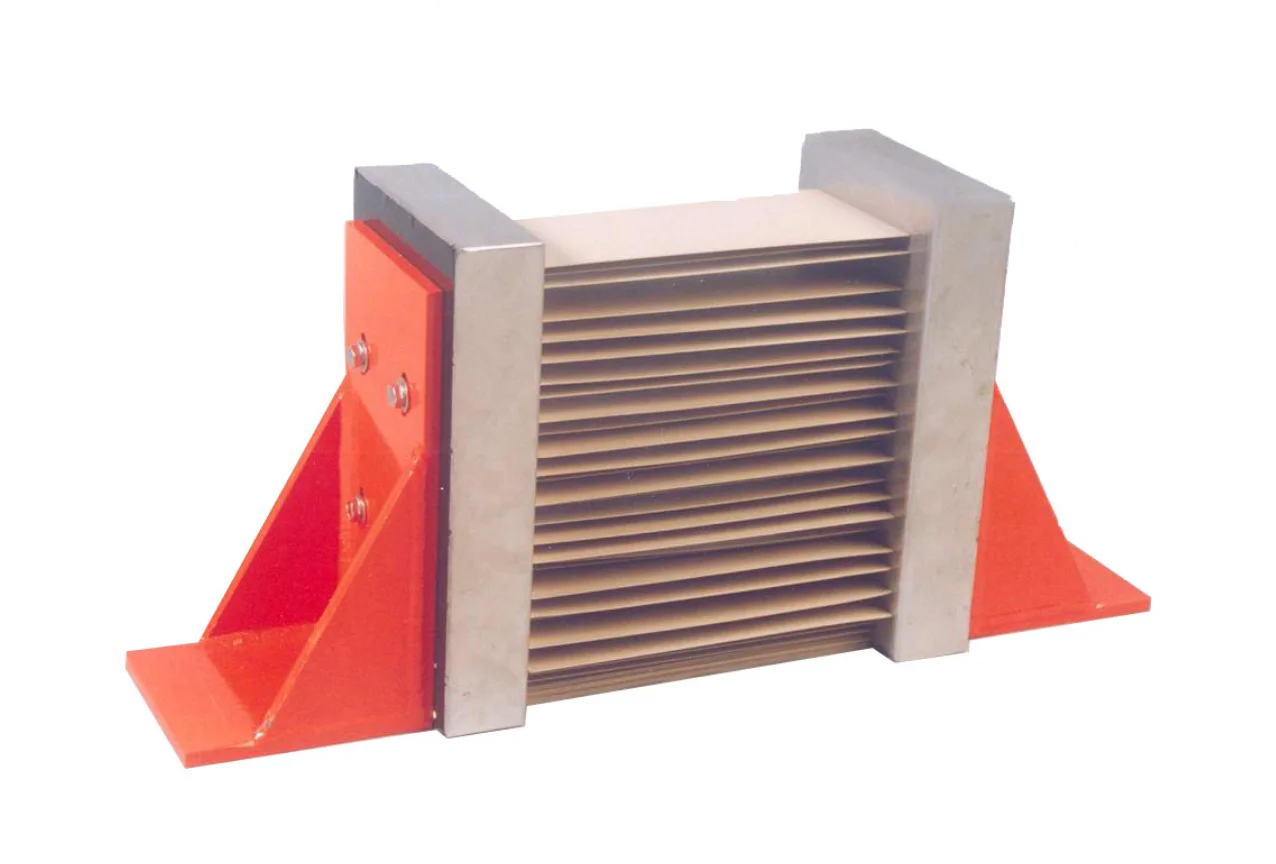

Usage of Magnetic Sheet Fanner

Magnetic sheet fanner, also known as magnetic sheet separators, are used to separate stacks of greasy or oily sheets in a safe and efficient manner. By using a strong magnetic field, the fanner can pull the sheets apart from each other, eliminating the need for operators to pry them apart manually. This can help to prevent damage to the sheets or injury to the operator. One advantage of magnetic sheet fanners is their modular design, which allows for a variety of mounting configurations to accommodate different sheet sizes and shapes. This makes them a versatile tool for a range of industrial and manufacturing applications.

Magnetic Sheet Separator for all Industries

Magnetic sheet fanner can be particularly useful in industries such as automotive manufacturing, where large sheets of metal are commonly used. The fanner can help to ensure that each sheet is separated and ready for use, which can improve overall efficiency and productivity. Magnetic sheet fanner is a valuable tool for any industry that uses stacks of metal sheets or other materials that can be difficult to separate manually. They offer a safe and efficient solution for separating sheets while minimizing the risk of damage or injury.

Permag Products – Leading Magnetic Equipment Manufacturer in India

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnet Audit, Magnet Testing, and Magnet Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

Magnetic sheet separators/fanners are available in a wide range of sizes and strengths, from handheld devices to bigger models with automatic sheet separation capabilities. The size and strength you select will be determined by the size and thickness of the sheets to be separated.

To keep your magnetic sheet separator/fanner in good working order, inspect it on a regular basis for symptoms of damage or wear. Using a moist cloth or brush, clean the surface of the magnets and any other tool components as needed. When not in use, keep the tool dry and away from any magnetic sources.

Magnetic sheet separators/fanners are generally safe to use if used correctly and according to the manufacturer’s recommendations. However, caution should be exercised when handling magnetic or ferrous material sheets to avoid harm or damage to the sheets.

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.