TRAP MAGNETS

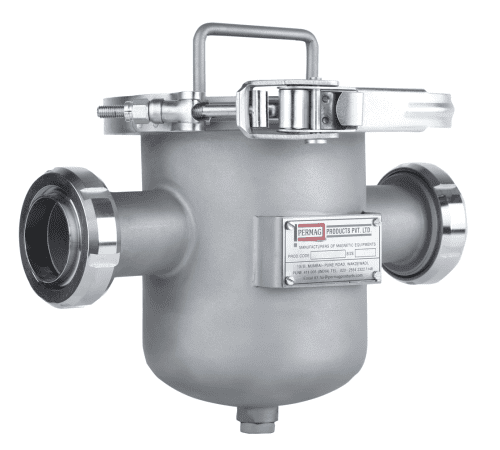

PERMAG’s high power liquid line trap Magnets & filter is designed to defend against ferrous and paramagnetic contamination in pressurized transfer lines.

To remove medium and fine ferrous contaminants from liquid lines and slurries, magnetic filter component is crucial. The Trap Magnets or Magnetic filter / Liquid Magnet trap / magnetic strainer filter is designed to be installed at important places in order to eliminate metal contamination from product streams, guarantee product quality, and avoid machine damage.

Trap magnets has a magnetic field that is incredibly powerful. Therefore, it is ideal for filtering small ferrous impurities as small as 30m. Standard in Permag’s filters are extremely powerful neodymium magnets that can resist temperatures up to 100°C

HOW TRAP MAGNETS WORK

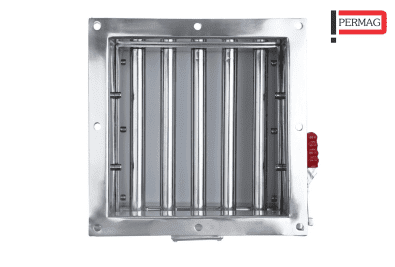

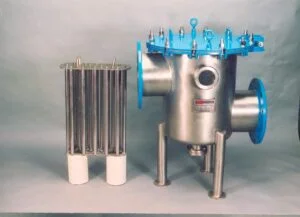

The Liquid trap magnet filters with extremely powerful RE magnetic rods are situated in the center of the product flow. As the product containing ferrous contamination flows through the traps/filters, it crosses many magnetic rods.

The magnetic rods draw ferrous impurities to themselves. The collected particles adhere to the magnetic rods, while the purified substance continues to flow.

For cleaning, detach the wing nut/clamp and remove the top lid with magnetic rods. Wipe the rods with a clean cloth to remove any ferrous contamination, then reattach the top lid. The duration of the cleaning procedure is three to five minutes.

TECHNICAL DATA SHEET OF TRAP MAGNETS

Magnet used – Nd-Fe-B (Rare earth)

Grade – N 52M (Highest grade)

FEATURES OF TRAP MAGNETS

304 / 316 Stainless steel, all-welded sturdy structure

Extremely potent premium grade N52M rare earth magnets

Available with 3000, 6000, 8000, 10000, and 12000 Gauss

Working temperature grade: 80, 100, 120, 150 degree Celsius

Simple to instal and requiring no maintenance

Remove up to 30 microns of metal

Superior filtration performance

Simple to clean

Custom length and diameter dimensions are available.

ADVANTAGES OF TRAP MAGNETS

Significant reduction in particle bypass through magnetic traps.

Magnetic flux circuit geometry ensures the controlled accumulation of contaminants, which lowers product stream bridging or clogging.

The elimination of ferrous material extends the life of machinery.

Reduce downtime and boost efficiency.

Compatible with all positions – vertical, horizontal, and oblique

What is Trap Magnet?

The trap magnet and Magnetic filter is made to protect pressurized transfer lines from ferrous and paramagnetic contamination. A magnetic filter component is a must-have for getting rid of medium and small ferrous particles from liquid lines and slurries. The Trap Magnets or trap Magnetic / Liquid Magnet trap filter / magnetic strainer filter / magnetic filter is made to be put in important places to keep metal from getting into product lines, make sure the quality of the product, and keep machines from breaking down.

Why Choose Us Magnetic Filter?

Magnetic filter provides magnetic protection for liquid lines and processing equipment. They do this by removing minute particles of magnetic scale, rust, and fine iron pollution that can be found in liquid product flows. This helps to maintain the product’s purity and keeps damage to the equipment to a minimum. Permag magnetic filter provide constant, consistent permanent-magnetic protection against tramp iron contamination. We provide a comprehensive range of products such as liquid magnetic trap separators, liquid line magnetic traps, and magnetic traps.

Characteristics of Liquid Magnet Trap

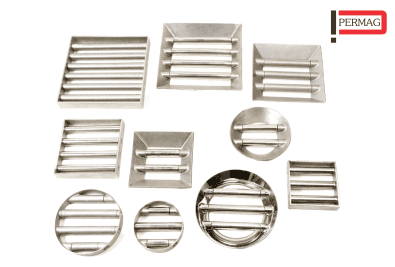

Liquid magnet trap are ideal for use with liquids, purees, and solids that are not fragile. These traps can be configured with multiple smaller tubes or a single large tube. The magnetic filter makes use of a slip-in cage that consists of one or more stainless steel permanent magnetic tubes. This helps to increase the product’s purity by capturing ferrous tramp metal particles. Tube-style Liquid magnet trap have the advantage that as metal particles collect, they migrate to the back of the tubes, where they remain protected from wash-off until the tubes are cleaned. This advantage is only available with tube-style Liquid magnet trap.

There are no set requirements for where the Tube Style magnet should be installed. Installing T-Traps in straight lines allows for total body drainage without the need for a sump area. Installation locations have to be such that metal collected by the magnet can be accessed easily for cleaning. Trap magnets can be mounted in any orientation, including vertical, horizontal, or sloped lines, and this will not compromise their magnetic efficiency.

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filter and Fixturers. Additionally, we offer Magnetic Audit, Magnetic Testing, and Magnetic Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Related Products

FAQ'S

Significant reduction in particle bypass through magnetic traps. Magnetic flux circuit geometry ensures the controlled accumulation of contaminants, which lowers product stream bridging or clogging. The elimination of ferrous material extends the life of machinery. Reduce downtime and boost efficiency. Compatible with all positions – vertical, horizontal, and oblique.

304 / 316 Stainless steel, all-welded sturdy structure Extremely potent premium grade N52M rare earth magnets Available with 3000, 6000, 8000, 10000, and 12000 Gauss Working temperature grade: 80, 100, 120, 150 degree Celsius Remove up to 30 microns of metal Custom length and diameter dimensions are available Simple to install and requiring no maintenance

The price of Magnetic T-Trap varies according to the size of the equipment it is being used in. Permag Magnetic T-Trap are one of the best for all industries, If you want to know more about the magnetic T-Trap, then you can contact us at ho@permagproducts.com

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.