MAGNETIC SEPARATOR MANUFACTURER

SLon, with its world-class R&D team specializing in High magnetic separation, has always prioritized cutting-edge technology. Through years of dedication, we’ve developed a range of patented products, successfully completing numerous national projects.

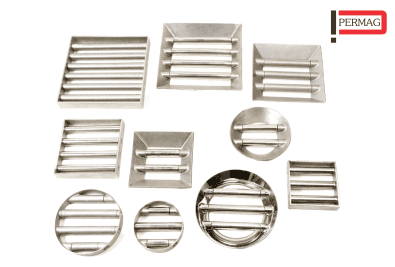

Magnetic Separator equipment is essential for removing ferrous contaminants in various industries, including grain, sugar, textiles, and pharmaceuticals. Our product range encompasses magnetic plates, rods, grills, filters, Hump Magnets, and more.

Permag Products is committed to achieving excellence, targeting 100% product qualification, customer satisfaction, and zero complaints. With our comprehensive quality management system, we oversee all stages, from design to after-sales service. Our goal is to provide effective magnetic separation solutions throughout India, always emphasizing quality and reliability.

We craft magnetic separators tailored to our clients’ unique requirements. By merging our expertise with their needs, we ensure optimal, cost-effective solutions. Our ongoing innovations and commitment to quality have made us a leader in India’s magnetic separator industry.

This version keeps the essence and key details of the original while presenting them in a more succinct manner.

How Magnetic Separator Manufacturer works

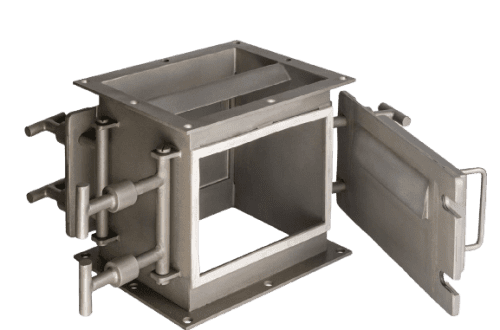

Due to its open-throat design, this open-throat design is able to process heavy flows of material that would otherwise choke or bridge over magnetic grates. Useful for powdery, lumpy, or wet materials when big tramp metals, such as nuts or bolts, endanger production or purity of the product.

Advantage of Magnetic Separator Manufacturer

Prevent damage to processing equipment

Maintaining a property is expensive.

Compared to a variant with a single plate

Compact design is more easily accommodated in confined locations.

A product that is metal-free saves energy.

Maintain a high level of efficiency

Application of Magnetic Separator Manufacturer

Feature of Magnetic Separator Manufacturer

This open-throat design makes it simple to operate while still maintaining high production rates.

Cleaning is a breeze with hinged magnets.

A variety of shapes and sizes are available for custom creation.

a long life expectancy

This is a sturdy and durable design.

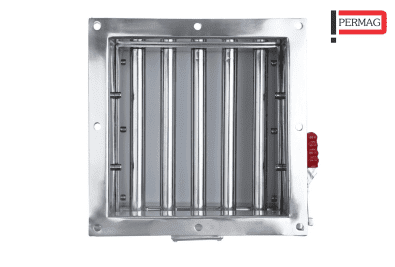

In SS 304, the entire structure is Thickness is 3mm

Technical Data Sheet Of Magnetic Separator Manufacturer

Magnet used – Nd-Fe-B (Rare earth) grade – N 52M (Highest grade)

Temperature – up to 100°C (higher temperature version available)

Surface finish – Glass bead

What is a Magnetic separator manufacturer?

A magnetic separator manufacturer is a company that designs, produces, and sells equipment used to separate magnetic materials from non-magnetic substances in various industries, such as mining, recycling, and manufacturing.

Remove ferrous impurities with Magnetic separator manufacturer

The deep reach separator is designed to extract tramp iron and ferrous particles from flow-resistant bulk materials. The separator is resistant to bridging and choking. The housings are made of stainless steel and are easy to attach either on the processing equipment directly or on enclosed spouting. To make the installation process easier, square, rectangular, and round adapters, which are optional, can be supplied according to your specifications.

Permag Products as a leading Magnetic separator manufacturer

We produce a deep reach separator that is constructed out of hefty material by default, and it is provided fully assembled with a heavy-duty plate magnet already fitted. The open-throat, choke-free design of our deep reach separator is combined with the safety and convenience of hinged magnets that swing out and away from the housing for easy, risk-free cleaning on the outside of the unit. The magnet plate that is provided has a rare earth magnet and a low intensity strontium Ferrite magnet.

Experience in the industry has allowed us to deliver a comprehensive range of Deep Reach Separator to our clients. These separators are renowned for their superior performance since they are precisely constructed to meet all of the relevant industry standards on our vendors’ end. The Deep Reach Separator, available in a number of configurations, is employed to purge harmful tramp iron from high-throughput flows of grain, chemicals, and powders. We are a leading magnetic separator manufacturer in India.

Permag Products offer some of the best magnetic equipment for all your magnetic needs. We offer – Grate Magnet, Hump Magnet, Magnetic Rod, Trap magnets, Magnetic Grill, Drawer Separator, Magnetic Filters and Fixturers. Additionally, we offer Magnet Audit, Magnet Testing, and Magnet Inspection for maintaining a high level of magnetic power in your magnetic equipment.

Characteristics of Magnetic separator manufacturer

- High-quality raw components are used in the construction of every Deep Reach Separator, and all manufacturing processes adhere to standard industry practices.

- Make use of hinged magnets for further security and comfort, and build it so that there is no way to accidentally choke yourself.

- To remove ferrous impurities from material passing through the chute, a Plate Magnet circuit was used.

- Tramp metals are efficiently removed because of their long reach into the product flow, as its name suggests.

- The best results are achieved with powder, lumpy, or damp materials, but they also work well with sticky goods.

- It can be used in a variety of fields, including the flour mill, chemical industry, foundry sand, minerals, the food industry, and more.

- No upkeep is required, so you can count on it running reliably and for a long time.

Related Products

FAQ'S

Due to its open-throat design, this open-throat design is able to process heavy flows of material that would otherwise choke or bridge over magnetic grates. Useful for powdery, lumpy, or wet materials when big tramp metals, such as nuts or bolts, endanger production or purity of the product.

Prevent damage to processing equipment, maintaining a property is expensive, Compared to a variant with a single plate Compact design is more easily accommodated in confined locations, A product that is metal-free saves energy, Maintain a high level of efficiency

Magnetic Separator Manufacturer Applied in following industries:

Food processing Industry, Pharmaceutical Industry, Chemical Industry, Dairy Industry, Paper Industry, Plastic Industry

Videos

TESTIMONIALS

What our customers have to say about our service

Optimize your process with magnetic equipment catered to your specific application. Know more from our experts.