In the vast landscape of industrial processes, efficiency and product quality are pivotal aspects that every industry strives to enhance. Among the multitude of tools and techniques, Drawer Separators, especially the magnetic variants like those offered by PERMAG, have emerged as indispensable components for achieving optimal separation efficiency. This article delves deep into the world of Drawer Separators, exploring their mechanisms, applications, and the role they play in ensuring product purity and machinery longevity.

Understanding Drawer Separators

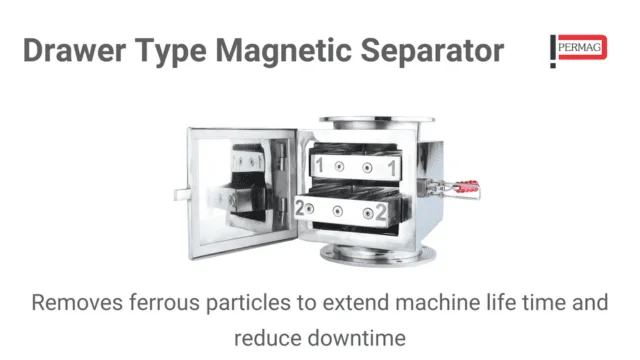

Drawer Separator, a critical part of the industrial separation equipment, serve the primary purpose of eliminating ferrous contamination from dry, free-flowing products. These separators leverage powerful magnets to achieve effective separation, making them an essential tool in maintaining the product quality and preventing damage to machines.

PERMAG’s drawer separator specifically provides powerful magnetic separation suitable for mechanical and gravity flow applications across various industries. The design and technology behind these separators allow for precise and efficient removal of medium and fine ferrous contamination, thereby enhancing the overall purity of the final product.

The Magnetic Marvel: How Drawer Separators Work

At the heart of Drawer Separators are high-power magnetic cartridges, an engineering marvel. These cartridges are designed with precision, configuring them into arrangements of two or more cartridge trays. The trays are staggered strategically to increase their contact with the product stream.

As the material moves through the separator, it follows a zig-zag pattern, passing from one cartridge tray to the next. This specific movement pattern maximizes the removal of ferrous contamination from the product stream, ensuring a high level of separation efficiency.

Applications Across Industries

Magnetic Drawer Separators find applications in a wide array of industries, owing to their versatile design and functionality. They are particularly valuable in mechanical and gravity flow applications, offering an efficient solution to remove metal contamination from product streams. These separators are typically placed at critical points within the production line to guarantee the quality of the final product and to safeguard machinery from potential damage caused by metal impurities.

Advantages of Utilizing Drawer Separators

1. Enhanced Product Quality

Drawer Separators, equipped with powerful magnetic cartridges, ensure that the end-products are of the highest quality by effectively removing ferrous contamination. This level of product quality is crucial for meeting industry standards and customer expectations.

2. Machinery Longevity

By preventing metal contamination and reducing wear and tear on machinery, Drawer Separators contribute to prolonging the lifespan of equipment, ultimately leading to cost savings for the industry.

3. Operational Flexibility

The versatility of Drawer Separators allows for their integration into various stages of the production process, offering flexibility in adapting to specific industry needs and requirements.

Implementing Drawer Separators: Best Practices

When incorporating Drawer Separators into a production line, it’s essential to consider a few best practices to ensure maximum efficiency:

- Strategic Placement: Identify critical points in the production line where metal contamination is most likely to occur and place the Drawer Separator accordingly.

- Regular Maintenance: Establish a routine maintenance schedule to clean and inspect the magnetic cartridges for optimal performance.

- Monitoring and Testing: Implement a monitoring system to regularly test the efficiency of the separator and make adjustments as needed.

- Employee Training: Ensure that personnel are trained to operate and maintain the Drawer Separator effectively.

Drawer Separators, particularly the magnetic variants offered by PERMAG, are instrumental in achieving high levels of separation efficiency within industrial processes. Their ability to remove ferrous contamination from product streams not only ensures product quality but also extends the life of machinery. By adopting these advanced separators and following best practices in their implementation, industries can significantly enhance their operational efficiency and maintain a consistent standard of product purity. Embrace the power of Drawer Separators and elevate your industrial processes to new heights of productivity and excellence.