In every manufacturing process, time is one of the most valuable resources. When machines stop, production halts, and costs increase. One of the leading causes of production downtime is contamination in raw materials. Small metal fragments such as iron filings, nails, or rust particles can damage machinery, affect product quality, and interrupt workflow.

Magnetic equipment, including grate magnets, plays a key role in preventing such issues. These devices help detect and remove ferrous contaminants at every stage of production. From handling raw materials to final packaging, they ensure cleaner operations, better product quality, and longer machine life.

This article explains how magnetic equipment such as grate magnets, magnetic grills, and separators help minimize downtime and improve efficiency in industrial production.

Why Magnetic Separation Matters in Manufacturing

Ferrous contamination can occur at any stage of manufacturing. It can come from worn-out machine parts, transport systems, or raw materials. Even small metal particles can cause big problems.

Magnetic separation equipment ensures that such impurities are removed before they cause damage. It keeps the production line running smoothly and protects expensive machinery.

Industries such as food processing, pharmaceuticals, plastics, and chemicals depend on reliable magnetic solutions to meet safety and quality standards. Using devices like grate magnets ensures compliance while reducing waste and downtime.

How Magnetic Equipment Works Throughout the Production Line

Every production line benefits from magnetic protection at multiple points. Let’s look at how magnetic equipment supports each stage.

Stage 1: Raw Material Inspection

Before materials enter the main processing system, they must be cleaned. At this stage, grate magnets and drawer magnets are highly effective.

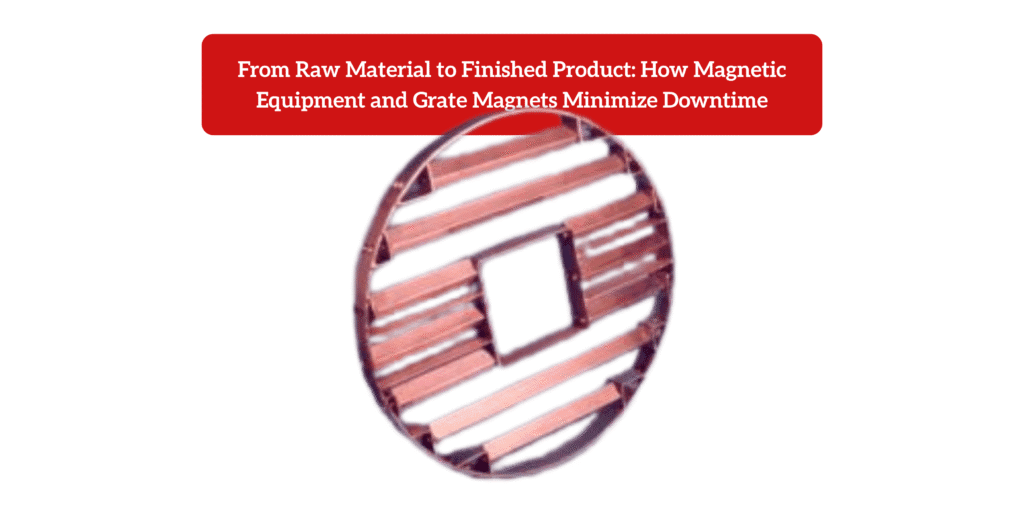

Placed inside hoppers, bins, and chutes, grate magnets capture fine iron particles and metallic debris that come with bulk materials. They are simple to install and easy to clean, making them one of the most efficient tools for pre-processing.

For larger contaminants, drum magnets on conveyor belts help separate unwanted metals before they enter grinding or mixing machinery.

Stage 2: Primary Processing

During crushing, grinding, or mixing, ferrous particles can damage blades or reduce machine performance. Plate magnets, hump magnets, and grate magnets help remove these particles from free-flowing powders, grains, or granules.

For wet or semi-liquid materials, magnetic filters and trap magnets are used to capture fine metal pieces suspended in fluids. This ensures clean processing and prevents clogging or leaks in pipes.

Stage 3: Secondary Processing and Mixing

At this stage, maintaining product purity is essential. Even minor contamination can ruin an entire batch.

- Suspension magnets remove any remaining ferrous fragments from materials moving on conveyor belts.

- Grate magnets are often reinstalled in blending and mixing lines to ensure final product consistency.

Their grid-like structure allows smooth material flow while trapping fine iron dust and metallic particles effectively.

Stage 4: Packaging and Final Quality Check

Even during packaging, contamination risks remain. Magnetic head pulleys at conveyor ends and grate magnets at hopper outlets ensure the final product is clean and safe.

These devices play a key role in industries like food and pharmaceuticals, where purity standards are strict. A final inspection using magnetic detectors guarantees that only contamination-free products are shipped.

Major Benefits of Using Grate Magnets and Magnetic Equipment

Reduced Downtime

By removing metal contaminants early, grate magnets prevent machine breakdowns and process interruptions. Continuous operation leads to higher productivity.

2. Longer Equipment Life

Clean materials reduce friction and wear on mechanical parts. This extends the lifespan of crushers, mixers, and conveyors.

3. Consistent Product Quality

With grate magnets installed, production lines maintain consistent purity levels. This improves brand trust and reduces product rejections.

4. Compliance with Safety Standards

Industries like food and pharma must follow strict hygiene regulations. Magnetic separation helps meet ISO and HACCP requirements with ease.

5. Cost Savings

Less contamination means fewer repairs, less waste, and more efficient use of resources. Over time, magnetic solutions pay for themselves.

How Permag Products Helps Manufacturers Reduce Downtime

Permag Products has been a trusted name in industrial magnetic solutions for over 35 years. We specialize in designing and manufacturing high-performance magnetic equipment for various applications.

Our range includes:

- Grate Magnets and Drawer Magnets for powders, granules, and free-flowing materials

- Hump Magnets for vertical pipelines

- Drum Magnets for conveyor-based separation

- Magnetic Filters and Traps for liquid and slurry systems

- Magnetic Head Pulleys for continuous cleaning of conveyors

Each product is made from durable materials and high-grade rare earth magnets for consistent performance. Permag’s experts also conduct magnetic audits and testing services to help clients maintain top-quality production lines with minimal downtime.

Our grate magnets are particularly popular because of their compact design, easy maintenance, and strong magnetic field. They are perfect for applications in food, plastic, and chemical industries where contamination control is crucial.

Real-World Example: How Grate Magnets Reduced Downtime

A plastic manufacturing plant faced frequent issues with small metal pieces contaminating its raw material. The problem led to repeated machine stoppages and product quality complaints.

Permag Products conducted an on-site magnetic audit and installed grate magnets and drum magnets at critical points in the process. Within a few weeks, the client noticed a 70% drop in equipment breakdowns and a visible improvement in product uniformity.

This simple yet effective solution saved them several hours of downtime each month, increasing overall productivity.

Best Practices for Using Grate Magnets

To get the best results, manufacturers should follow a few key practices:

- Regular Cleaning: Clean grate magnets periodically to maintain magnetic strength and efficiency.

- Scheduled Inspection: Check for buildup of metal particles and ensure magnets are free from damage.

- Proper Placement: Position magnets at points where contamination is most likely to occur.

- Testing and Maintenance: Conduct Gauss tests to ensure magnets retain full strength.

Consult Experts: Work with professionals like Permag Products

to design the right configuration for your production line.

The Bottom Line

Every manufacturer wants to reduce downtime and maintain consistent output. Magnetic equipment such as grate magnets, magnetic grills, and separators make this possible. They help eliminate ferrous contaminants, protect machines, and ensure smooth production from raw material handling to packaging.

With decades of experience, Permag Products continues to deliver reliable magnetic solutions that enhance productivity and product safety. Our grate magnets and other magnetic systems are built for long-term performance and easy integration into existing lines.

If your manufacturing process struggles with contamination or unplanned downtime, contact Permag Products today. Our team can help you choose the right grate magnet or magnetic separator to keep your production running efficiently and safely.