In the realm of industrial processes across various sectors, maintaining product purity is paramount. The presence of ferrous contaminants in dry, free-flowing products poses a challenge, potentially compromising product quality and damaging machinery. Enter Drawer Magnet Separators, a robust solution engineered to address this concern by employing powerful magnetic separation.

Understanding the Role of Drawer Magnet Separators

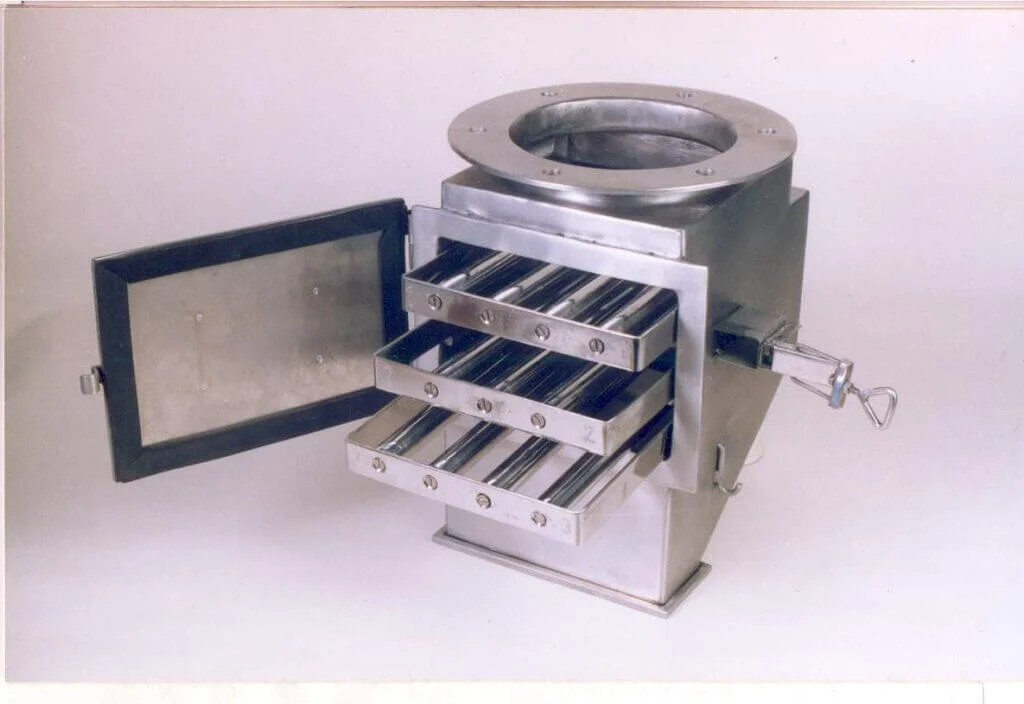

PERMAG’s Drawer Separator stands as a stalwart in magnetic separation technology, offering powerful and effective ferrous contamination removal. These separators find application across mechanical and gravity flow setups in diverse industries, safeguarding product quality and machinery integrity.

Elevating Product Purity

Magnetic Drawer Separators play a pivotal role in eliminating medium and fine ferrous contamination from product streams. Their strategic placement at critical points ensures a seamless extraction process, guaranteeing the purity of dry, free-flowing products crucial across industries.

The Ingenious Design Behind Efficiency

Equipped with high-power magnetic cartridges, Drawer Magnet Separators boast arrangements of multiple cartridge trays strategically staggered to maximize contact with the product stream. This configuration allows materials to traverse in a zig-zag pattern, efficiently maximizing the removal of ferrous contaminants with each tray transition.

Promoting Quality Assurance

The primary objective of these separators is to assure product quality and prevent machinery damage by removing metal contamination. By acting as a vigilant gatekeeper at critical junctures, they ensure that products remain uncontaminated, meeting stringent quality standards.

Versatility in Application

The versatility of Drawer Magnet Separators shines through their applicability in a wide array of industries. From food processing to pharmaceuticals, plastics, and beyond, these separators serve as guardians, upholding product integrity across multiple sectors.

Ensuring Efficiency and Reliability

Beyond their effectiveness in contamination removal, these separators are engineered for reliability. Their design, coupled with high-quality materials, ensures operational efficiency and longevity, contributing to uninterrupted manufacturing processes.

Drawer Magnet Separators stand as a testament to innovation and efficiency in maintaining product purity. Their role in eliminating ferrous contaminants from product streams is integral, safeguarding product quality and machinery integrity across industries. As a cornerstone of magnetic separation technology, these separators continue to elevate industry standards, ensuring the delivery of uncompromised, high-quality products to consumers worldwide.