Ensuring product purity and safety is one of the biggest responsibilities in food and pharmaceutical manufacturing. Even tiny metal contaminants can cause major issues,product recalls, damage to equipment, harm to consumers, and loss of brand reputation. That’s why magnetic separation systems, especially the Hump Magnet, are widely used in industries where high-quality standards are non-negotiable.

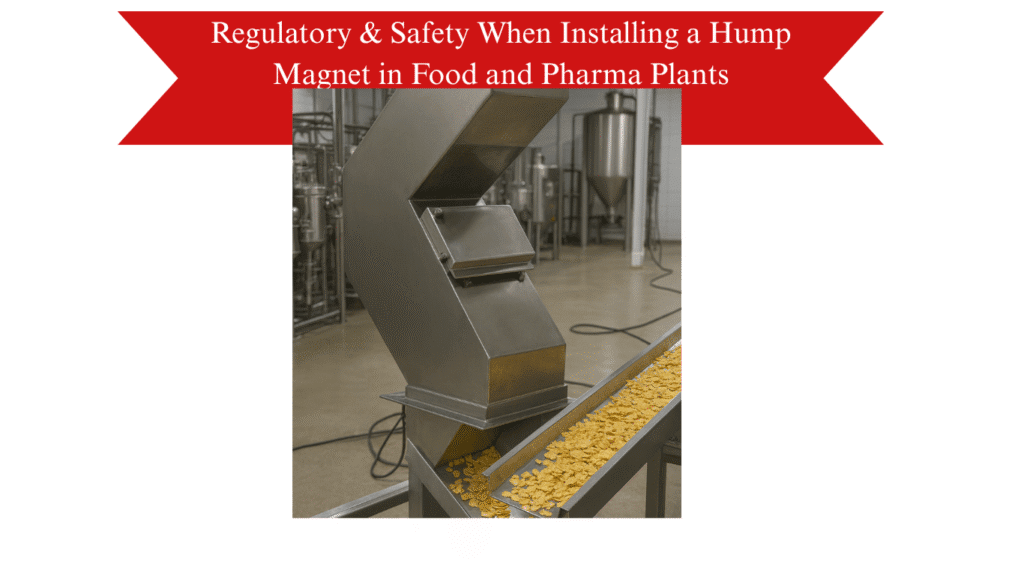

A Hump Magnet is specially designed to remove ferrous metal contamination from gravity-fed materials such as grains, sugar, powders, chemicals, granules, and capsules. But installing one is not just about fitting it into a pipeline. Food and pharma manufacturers must follow strict regulatory standards, safety guidelines, and hygiene requirements. A poorly selected or poorly installed Hump Magnet can lead to compliance violations, unsafe working conditions, and ineffective separation.

This blog explains all the important regulatory and safety considerations you must know before installing a Hump Magnet in a food or pharmaceutical plant. Whether you are an engineer, quality manager, plant head, or procurement officer, this guide will help you make a compliant and safe installation decision.

Why Magnet Installation Needs Regulatory Compliance

Every food or pharma plant must deliver products that are free from physical contaminants. Regulatory bodies like FSSAI, FDA, WHO-GMP, HACCP, BRCGS, ISO 22000, and others specify strict guidelines to prevent contamination.

A Hump Magnet is considered a “Critical Control Point” (CCP) in many plants, meaning it plays a direct role in ensuring consumer safety. If it fails, contaminated products can reach the market. Since the Hump Magnet becomes part of your processing line, its installation must align with hygiene, safety, and operational guidelines defined by global and local regulatory authorities.

Choosing the Right Hump Magnet Material: The Role of Stainless Steel Standards

The material of construction is one of the first regulatory considerations.

Food and pharma plants should select Hump Magnets made from:

SS304 or SS316 Food-Grade Stainless Steel

These grades are corrosion-resistant, smooth, hygienic, and approved for contact with food and medicines.

- SS304 is suitable for dry, low-moisture applications.

- SS316 offers higher resistance to chemicals and is required in pharma or harsh environments.

Regulations like FDA and HACCP clearly stress using non-toxic, non-corrosive, easy-to-clean materials. A Hump Magnet made from inferior metal may leach contaminants, rust, or harbor bacteria,all of which are compliance violations.

Choosing Food-Grade Seals, Gaskets & Wedges

A Hump Magnet installed in a pipeline must be airtight, leak-proof, and dust-free. This requires food-safe sealing materials.

Most standards recommend:

- Silicone food-grade gaskets

- NBR food-safe rubber

- EPDM food-grade sealing

Using industrial-grade or unknown-quality seals can lead to contamination, microbial growth, or chemical reactions. Regulatory bodies conduct audits specifically checking gasket and seal quality.

Magnetic Strength Requirements for Food & Pharma Applications

Regulations do not always list exact magnetic strengths, but industry guidelines provide strong recommendations to ensure effective separation.

A high-quality Hump Magnet should deliver:

- 10,000 – 12,000 Gauss for food powders, spices, sugar, coffee, tea, chemicals

- 8,000 – 10,000 Gauss for pharmaceutical granules, capsules, excipients

- 5,000 – 7,000 Gauss for coarse grains, cereals, seeds

Weaker magnets may allow metal fragments to pass through, increasing contamination risk.

Before installation, a Magnetic Audit should be conducted to check:

-Gauss reading

-Magnetic pull strength

-Magnet integrity

-Surface wear and tear

Some regulatory standards expect periodic re-testing to ensure magnets continue to perform effectively.

Ensuring Compliance with Cleaning and Hygiene Standards

A major safety consideration with Hump Magnets is regular cleaning. Metallic contaminants collected on the magnet must be removed at scheduled intervals. In food and pharma plants, this is crucial for:

- Preventing microbial growth

- Avoiding product buildup

- Maintaining metal separation effectiveness

- Ensuring equipment durability

Regulatory expectations include:

- Maintaining cleaning logs

- Having documented SOPs

- Ensuring magnets can be safely accessed

- Using gloves, safety equipment, and lock-out/tag-out procedures during cleaning

Most modern Hump Magnets come with swing-open doors or quick-clean designs. These reduce downtime and enable safe, hygienic cleaning without dismantling the entire unit.

Proper Placement of a Hump Magnet in the Production Line

The location of the magnet in the process matters for regulatory compliance.

Correct placement helps in:

- Ensuring maximum removal of metal contaminants

- Reducing the load on downstream equipment (mills, grinders, packaging machines)

- Preventing cross-contamination

- Maintaining consistent product flow

A Hump Magnet is generally installed in vertical gravity-fed pipelines, especially where product flow is fast and free-falling. The hump design forces material to change direction twice, increasing magnetic contact.

Regulations also expect:

- No blockage or product stagnation

- Easy accessibility for inspection

- Safe working height and load-bearing support

- No dead corners where product can accumulate

Sealed connections to prevent dusting or spillage

Documentation & Traceability for Audit Compliance

Food and pharma industries must maintain strict documentation for every CCP, including magnetic separators.

Your records should include:

- Hump Magnet model, serial number, and manufacturer details

- Magnetic test certificates

- Installation diagrams

- Cleaning logs

- Maintenance reports

- CCP monitoring reports

- Annual or quarterly magnetic strength audit details

- Corrective action records (if metal contamination is found)

During audits, inspectors will ask for documentation to verify that the Hump Magnet is serviced, monitored, and functioning properly.

Worker Safety During Installation & Maintenance

Beyond product safety, worker safety is also critical. Magnets are powerful devices that must be handled carefully.

Safety precautions include:

- Using protective gloves during cleaning

- Preventing fingers from getting caught between magnetic plates

- Avoiding exposure to sharp metal fragments collected on the magnet

- Ensuring magnets are demagnetized before certain repairs

- Using lift-assist tools for heavy magnetic plates

- Following lock-out/tag-out (LOTO) during inspection and maintenance

- Ensuring the magnet is installed at a safe, ergonomic height

- Providing training to staff on safe handling of magnets

Neglecting safety can lead to injuries, equipment damage, and regulatory penalties.

Ensuring the Hump Magnet Meets International Standards

Many plants export food and pharmaceuticals globally. In such cases, your Hump Magnet must comply with international standards.

The most relevant ones include:

Food Regulations:

- FSSAI

- FDA (Title 21 CFR)

- HACCP

- BRCGS

- ISO 22000

- Codex Alimentarius

Pharma Regulations:

- WHO-GMP

- EU-GMP

- FDA cGMP

- PIC/S standards

Equipment Standards:

- ASME standards for pressure/structural integrity

- Welding and finishing standards for stainless steel

- Magnetic testing standards

Compliance ensures safer products, smoother audits, and approval for international markets

Regular Magnetic Testing & Performance Verification

Installing a Hump Magnet is not enough. You must ensure it continues to perform effectively.

Regulations recommend:

- Quarterly magnetic audits

- Annual third-party certification

- Routine internal inspections

- Replacing worn magnets immediately

Magnet performance naturally degrades over time due to:

- Heat

- Moisture

- Mechanical impact

- Excessive buildup

- General wear and tear

Testing ensures the magnet remains strong enough to capture fine metal particles.

Conclusion

A Hump Magnet is an essential safety device in food and pharmaceutical manufacturing. But installing it correctly,while following regulatory and safety standards,is just as important as choosing the right equipment. From selecting food-grade materials to ensuring magnetic strength, hygienic design, proper placement, worker safety, and full documentation, every detail matters.

When installed and maintained properly, a Hump Magnet can:

- Prevent contamination

- Reduce equipment damage

- Ensure audit compliance

- Protect consumer health

- Improve overall product quality

If you follow the guidelines discussed in this blog, your plant will remain compliant, safe, and efficient, and your Hump Magnet will deliver maximum performance for years to come.